Cutting Boards M

Item Name

Cutting Boards M

Size

M 150mm×200mm×30mm

Use

It is used as a bedding plate when punching holes in leather with Diamond hole punches, etc.

Can be used for Round Hole Drive Punches, Skiving Knives, and Cutters.

Characteristics

These are Cutting Boards made by a factory specializing in leather craft tools.

We are particular about the hardness of cutting boards, which is most suitable for the hardness of metals such as diamond hole punches and round hole drive punches that we manufacture.

・

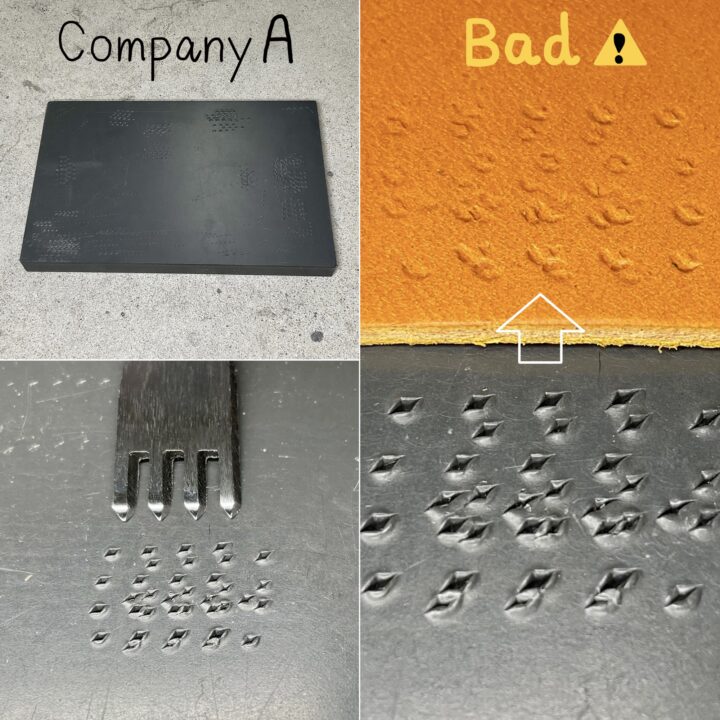

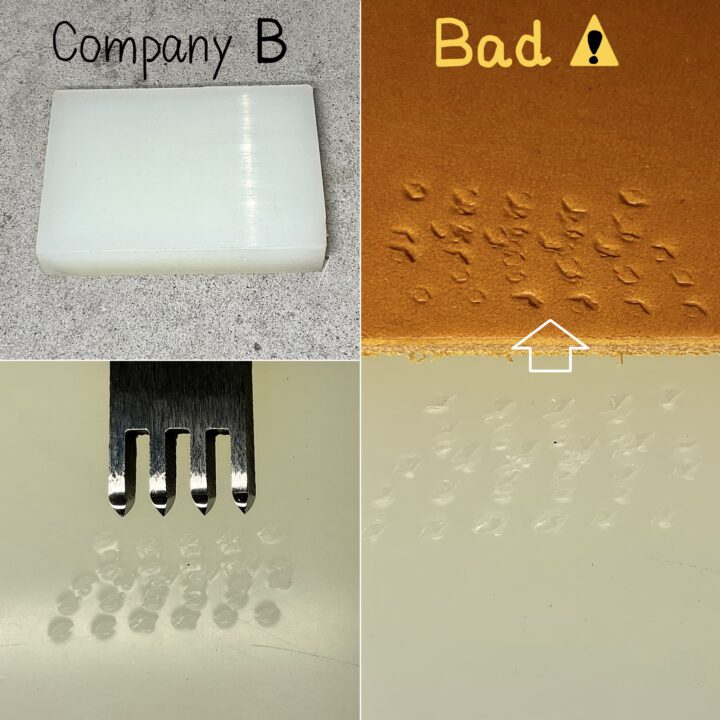

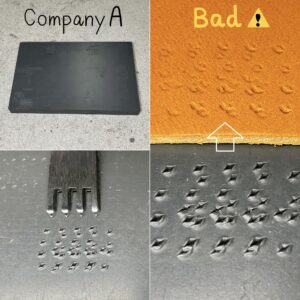

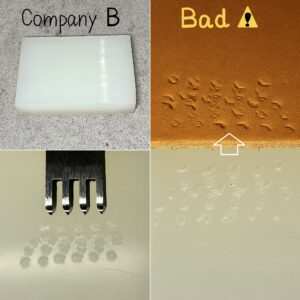

Cutting Boards up to now had [three disadvantages] due to their hardness.

(1) Damage to the blade of diamond hole punches, which are blades.

(2) The raised corners from striking the diamond hole punches leave scars on the leather.

(3) Noisy sound due to repulsion when tapped.

・

We have developed [cutting boards that are gentle to tools and stress-free].

In the old days, Japanese leather craftsmen used thick wooden cutting boards, or sitting cross-legged on logs, to punch holes in leather with diamond hole punches.

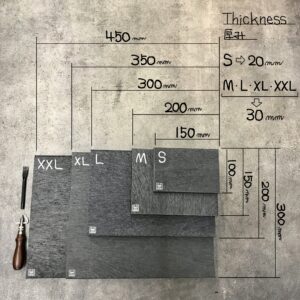

Taking a cue from this history and tradition, we rethought Cutting Boards from the ground up and created Cutting Boards with a wood grain tone that is gentle to blades.

The fine bumps in the wood grain pattern allow the leather to conform to the Cutting Boards and also serve as a non-slip surface.

・

[Characteristics]

-Cutting Boards deformation-

We have improved the deformation of the Cutting Boards when drilling holes by focusing on the materials of the Cutting Boards.

The grain side of the leather will not show scratches caused by the Cutting Boards even if they are tapped on the bottom.

・

-In terms of improving the sharpness of diamond hole punches-

The hardness was made so that Diamond hole punches can be penetrated easily with less force.

If the Cutting Boards are hard, they will rebound, making it difficult for diamond hole punches to penetrate.

・

-About the hardness of the Cutting Boards-

We are particular about the hardness of Cutting Boards.

Our Diamond hole punches are tempered by selecting metal hardnesses suitable for leather craft.

From the perspective of a factory specializing in leather craft tools, we have created Cutting Boards with the hardness we want users to use.

・

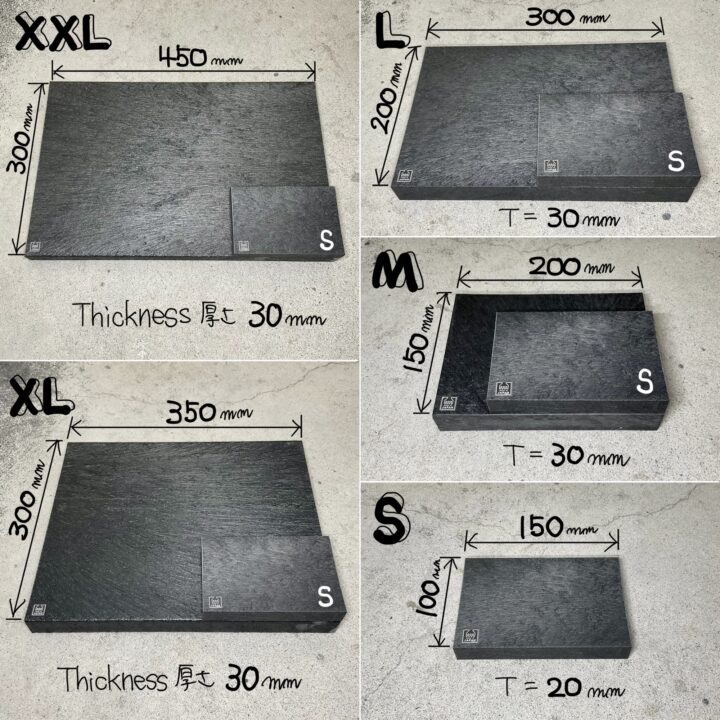

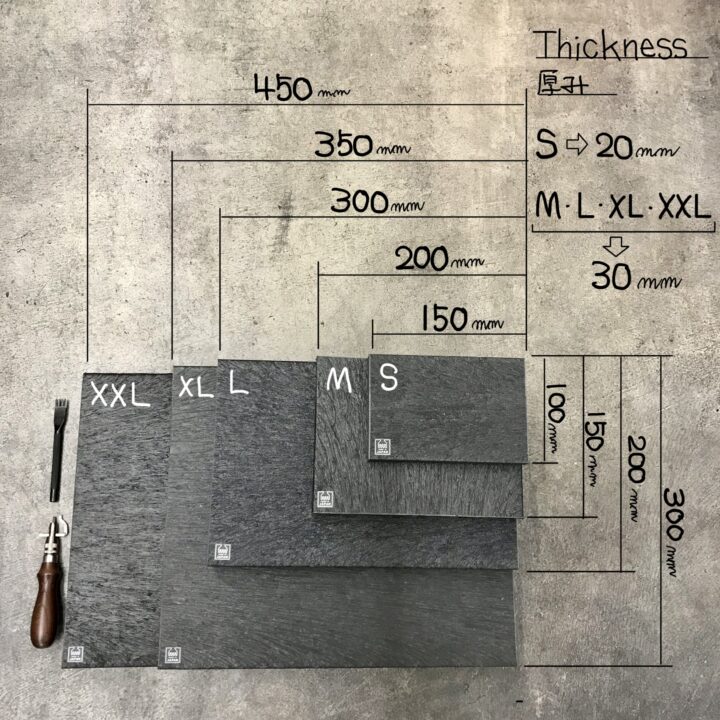

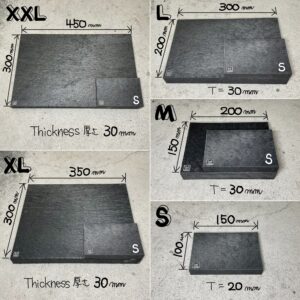

-The benefits of thickness-

The thickness of the board is 30mm, which has never been seen before in Cutting Boards.

There are three advantages to having the thickness of Cutting Boards.

(1) Diamond hole punches are more stable.

(2) Quieter striking sound compared to thin Cutting Boards.

(3) Because of its weight, it does not rebound when struck.

(20mm thick only for S/Small)

・

-About Stickers-

It has proven to be suitable for Diamond hole punches and leather crafts.

Manufactured in Japan.

・

-Length x width x height-

S 100mm×150mm×20mm

M 150mm×200mm×30mm

L 200mm×300mm×30mm

XL 300mm×350mm×30mm

XXL 300mm×450mm×30mm

・

-About Maintenance-

Roller and Clothes iron can be used to correct used rubber plates.

・

-About the price-

Cutting Boards, like vinyl boards and cutting boards for cooking, are consumable items, making them reasonably priced and affordable.

It is economical because both the front and back surfaces can be used.

・

【Caution】

Diamond hole punches should not penetrate deeply into Cutting Boards.

It may cause the tip of the blade to break.

It is the same principle as putting the blade of diamond hole punches in a vise and swinging it back and forth, left and right.

As long as the tip of the blade is sticking out of the leather, you are good to go.

Whether diamond hole punches are inserted deeply into the leather or shallowly, the stitches remain the same.

Usage & Maintenance

User's Manual

-

Related items

Please feel free to inquire about anything and also asking for quotations.

Oka Factory & Co.,Ltd.

272-0827 5-10-7, Konodai, Ichikawa-city, Chiba

Monday - Friday, 8:30 a.m. - 6:00 p.m.

FAX +81-47-713-8661