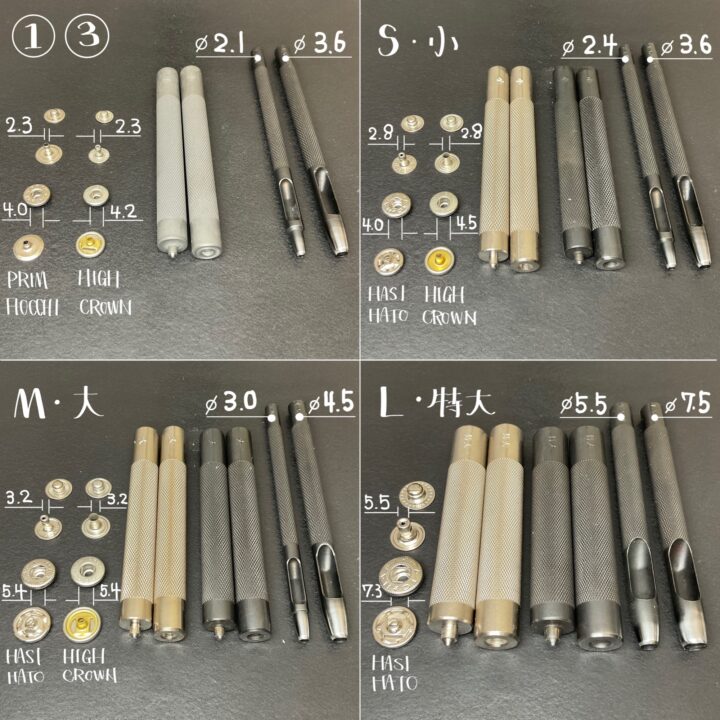

Spring Snap Setter (①・③) Tempered

Pro Spring Snap Setters (Tempered) Strong durability

Item Name

Spring Snap Setter (①・③) Tempered

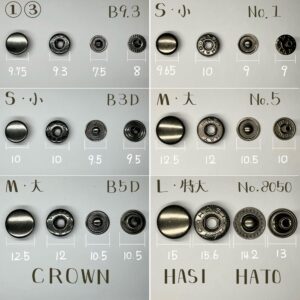

Size

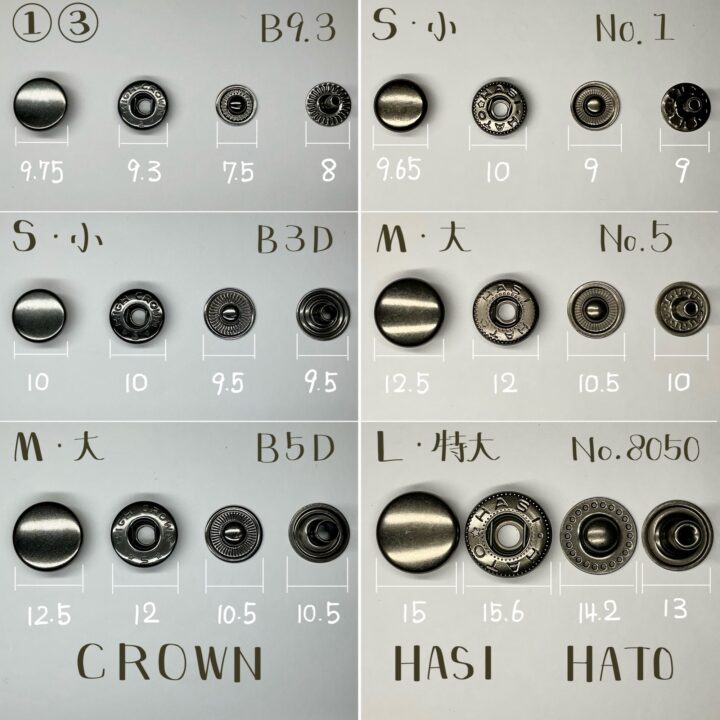

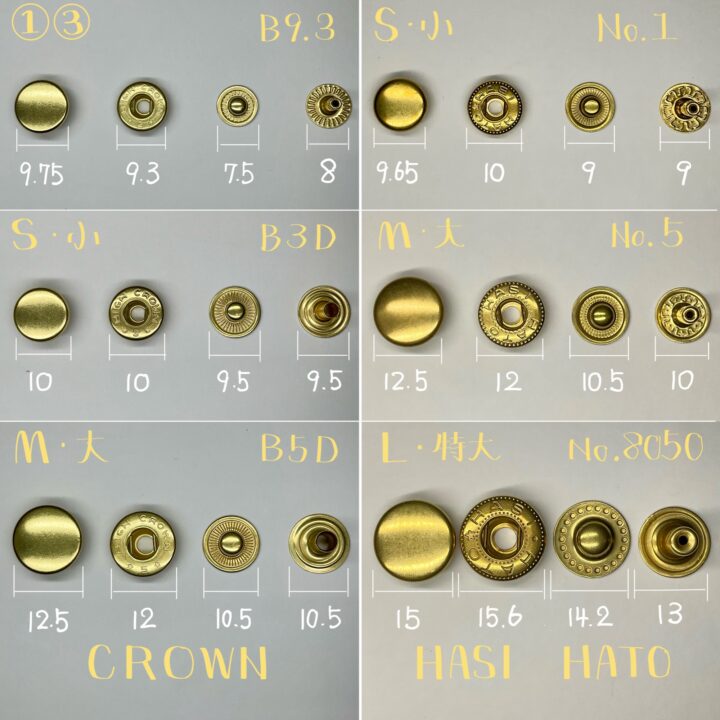

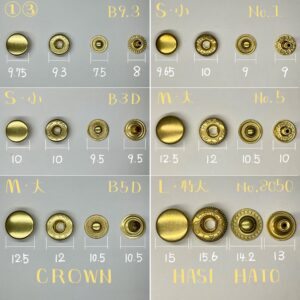

B9.3(CROWN)/ 9.3mm(PRYM)

Use

Exclusive for Spring snap metal fittings.

Please use the appropriate setter for the size of metal fittings.

Characteristics

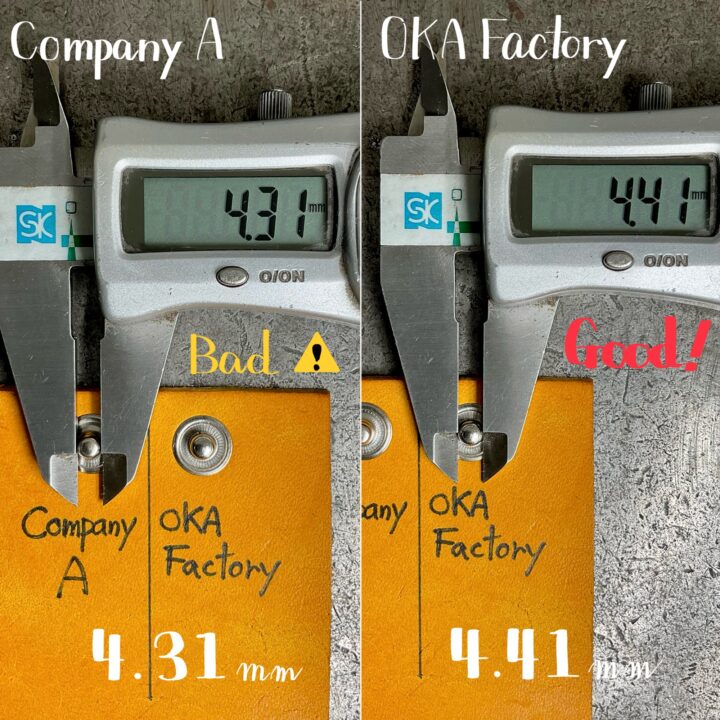

Conventional spring snap setters could not demonstrate the original fixing strength of the metal fittings.

Causes include.

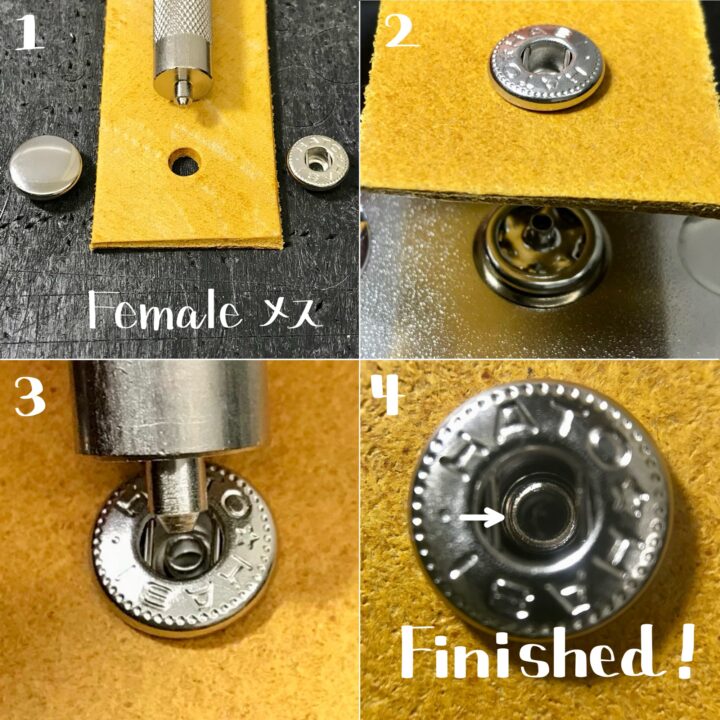

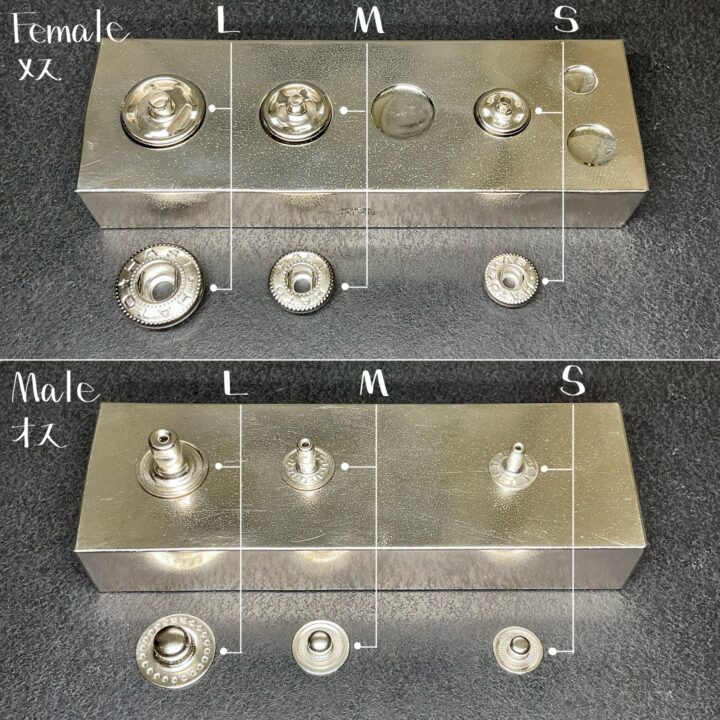

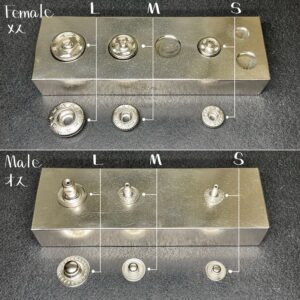

[Setter for female spring snap metal fitting]

The pipe part of the metal fittings is circular, but the setter is rectangular only for the purpose of being inserted into the metal fitting.

The rectangular shape does not allow the metal fitting pipe to curl cleanly 360°. (3rd image)

Therefore, when opening and closing the metal fitting, the metal fitting often came off the leather.

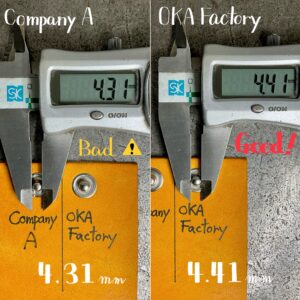

[Setter for male spring snap metal fitting]

The hole in the spring snap setter is too deep, causing the male metal fitting to stretch and deform.

The male metal fitting is stretched and not firmly secured to the two springs.

Metal fitting cannot exhibit its original fixing strength and is easily dislodged. (4th and 5th images)

・

We have developed a setter that can demonstrate the original fixing force of metal fittings.

[Setter for female spring snap metal fitting]

We were particular about curling the metal fitting pipe cleanly through 360°.

Since the metal fitting is fixed at 360°, it is difficult to remove the metal fitting no matter which direction the force is applied.

[Setter for male spring snap metal fitting]

The shape and depth of the holes in the Setter have been carefully selected.

It is most important to secure the male metal fitting to the leather without deforming it.

The sound of the metal fitting when it is opened and closed is completely different from that of other companies' products, so please compare the sound.

I have never seen a manufacturer that is so particular about what they make, so I would love to see a comparison.

You can experience the inherently strong fixing force of spring snap metal fittings.

・

【About spring snap setters】

This is a standard product with Nickel plate processing.

It is intended for use in the beginner to hobbyist range.

It can stop a considerable number of fittings, but is intended for those who use it infrequently.

・

【About Pro spring snap setters】

The entire ring snap setter is tempered to improve abrasion resistance.

This product is intended for professional craftsmen and those who use it frequently.

The tempered finish dramatically increases the hardness of the metal, making it very long-lasting.

After tempered, the actual hardness is measured with a metal hardness tester to ensure that the required hardness is maintained, unannounced.

The tip of the Ring Snap Setter is further polished and protected with a resin coating before shipping.

The entire surface is treated with a black coating to prevent rust.

・

【Characteristics】

Female metal fittings are mirror-finished to match the pipe shape of the metal fitting.

The mirror finish allows the metal fitting pipe to be curled and secured 360° without resistance.

The Male Spring snap setter is particular about the hole diameter and depth and does not deform the male fittings.

We aim to make it easy for anyone to cleanly stop metal fitting.

・

The handles are treated with an ayame finish to prevent slipping.

The hand does not go haywire, so work can be performed reliably.

・

The entire spring snap setter is Nickel plated to prevent rust.

Pro spring snap setter is coated with black coating to prevent rust.

・

The end of the spring snap setter is imprinted with [size indication] and [MADE IN JAPAN].

[Size Indication]

S = 小

M = 大

L = 特大

・

【Caution】

When stopping the female metal fitting, do not hit it with strong force at one time. (It may not stop properly.)

Push the two springs of the female metal fitting apart with the tip of the spring snap setter and tap them against the pipe of the female metal fitting two to four times to stop them.

The trick is to finish the female metal fitting without applying the spring snap setter to the HASI HATO logo.

・

Do not use a hammer when tapping.

Ring snap setter deformation may cause rusting.

Wood Hammer Maul, Round Maul, and mallet are recommended.

Usage & Maintenance

-

User's Manual

-

Related items

Please feel free to inquire about anything and also asking for quotations.

Oka Factory & Co.,Ltd.

272-0827 5-10-7, Konodai, Ichikawa-city, Chiba

Monday - Friday, 8:30 a.m. - 6:00 p.m.

FAX +81-47-713-8661