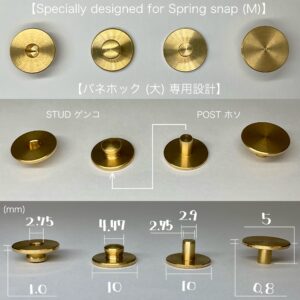

【OKA Factory】Lathe machining STUD (Specially designed for Spring snap) M (Solid brass)

Lathe machining STUD (Spring snap) M【OKA Factory】

Item Name

【OKA Factory】Lathe machining STUD (Specially designed for Spring snap) M (Solid brass)

Size

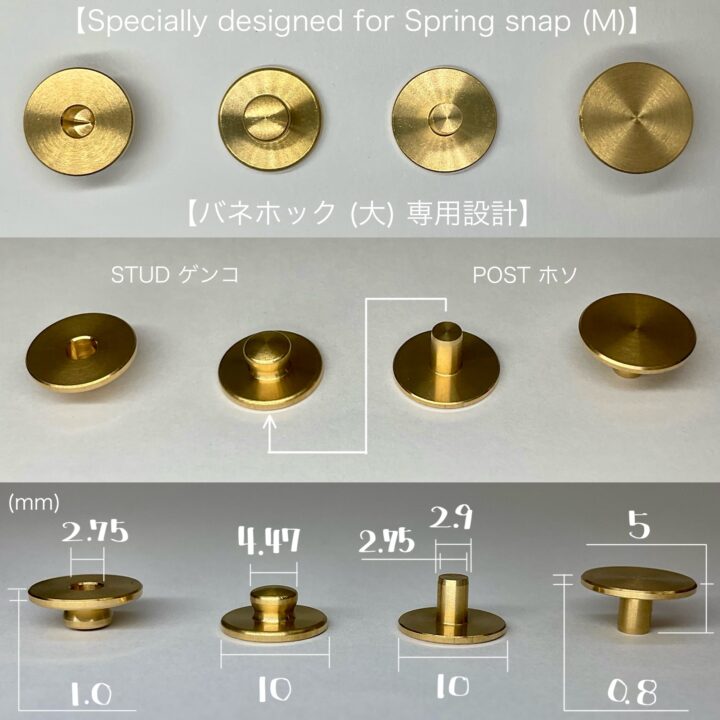

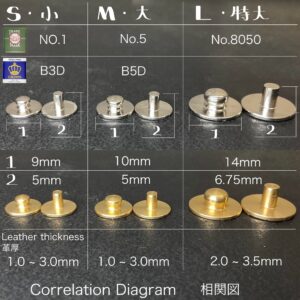

Outer diameter 10mm (Spring snap M) Fits: HASI HATO No.5/ CROWN B5D

Use

Lathe machining STUD for spring snap fittings

(STUD means a male fitting)

Spring snap fittings consist of four parts

CAP = 頭

SOCKET = バネ

STUD = ゲンコ

POST = ホソ

*Regarding【OKA Factory】Lathe machining STUD (Spring snap),

This product does not include “CAP & SOCKET” parts, so please prepare them separately.

Characteristics

【Lathe machining STUD for Spring snap metal fittings made in Japan by a factory specializing in leather craft tools !】

We were particular about [five points].

1. To give the product an unprecedented sense of luxury.

2. That it can be used in common with the HASI HATO/ CROWN.

3. Our existing tools can be used.

4. No thickness should appear when spring snap metal fittings are installed.

5. Spring snaps shall not be deformed.

For the development, HASI HATO and CROWN fittings were drawn up and the dimensions that could be shared were calculated.

We quantified the subtle sensation of Spring spreading and closing, and created it with [a shape that stops with a click] in mind.

These Metal fittings created from the perspective of a factory specializing in leather craft tools.

We have given shape to the idea of "what I wish spring snap metal fitting s were like" when I do leather crafts.

【100% OKA Factory Original product !】

【Characteristics】

1.【To give the product an unprecedented sense of luxury.】

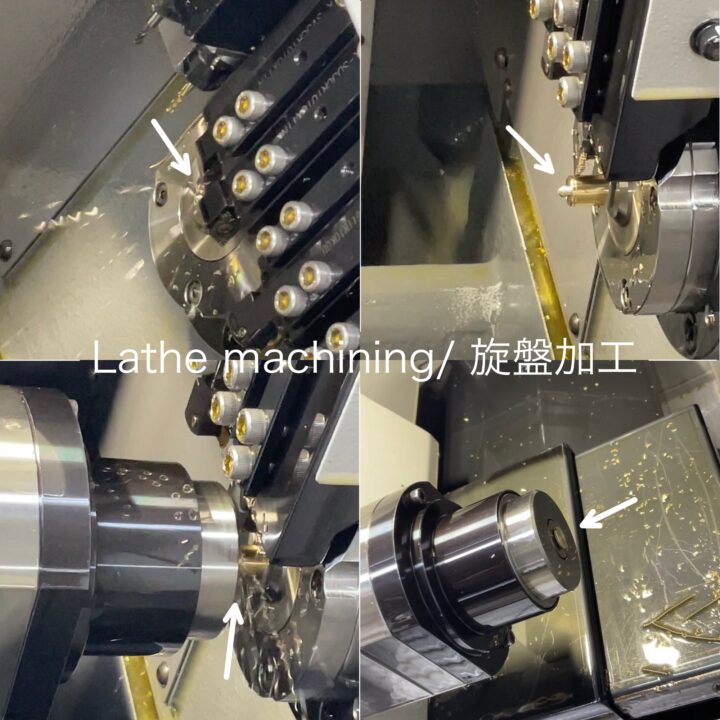

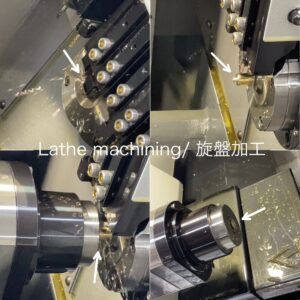

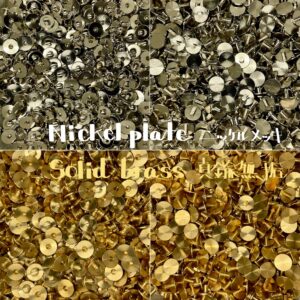

STUDs for regular products are processed by press machines

Because precision and mass production are required, the metal cannot be made thicker.

The lack of thickness in the metal inevitably makes the metal fittings appear inexpensive.

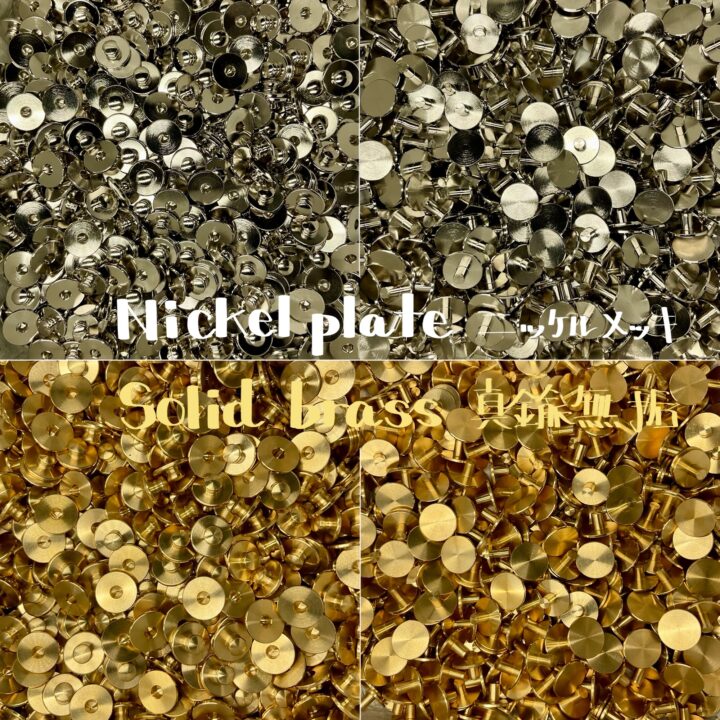

We insist on lathe machining for both STUD and POST because we want our metal fittings to have a "one-of-a-kind, high-end feel" rather than mass production.

We were conscious of [simple and modern design].

Compared to mass-produced stamped products, the unique character of Lathe machining can give your work a luxurious feel.

We hope you will use it for your special work of art.

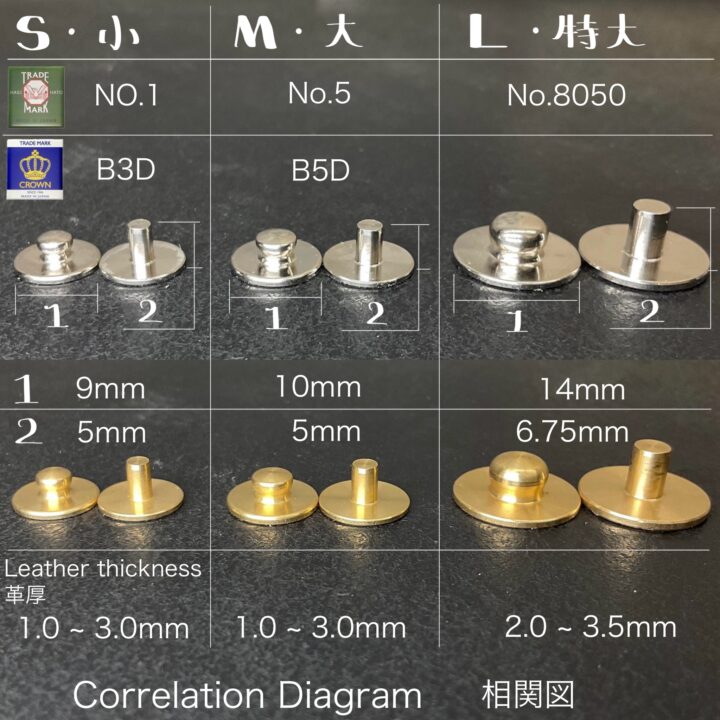

2.【That it can be used in common with the HASI HATO/ CROWN.】

We usually manufacture setters that fit HASI HATO and CROWN fittings.

With years of experience making these tools, we know what doesn't work and what does.

By quantifying the two brands, we were able to calculate the size that they can share.

This allowed us to develop a fitting that allows both brands of Spring Snaps to be used with our original STUD.

(*Refer to the 2nd, 4th and 10th images)

3.【Our existing tools can be used.】

Until now, the Lathe machining STUD has been PRIM/ FIOCCHI 9.3mm OD.

This Lathe machining STUD required a special setter due to its mountainous shape.

(See PRIM/ FIOCCHI metal fitting setter② manufactured by our company)

With our Lathe machining STUD, you do not need to buy a new dedicated Setter.

We have made a design that can be used with our existing spring snap setters.

You only need to purchase the hardware and you are ready to go.

4.【No thickness should appear when spring snap metal fittings are installed.】

PRIM/ FIOCCHI lathe machining STUD is a mountain shape.

Due to its mountainous shape, the spring snap metal fitting inevitably results in a wasted thickness.

This unnecessary thickness is a disadvantage, especially for small items that you want to carry smartly, such as a wallet, business card case, etc.

We have eliminated all this waste and focused on a simple, modern design.

With Lathe machining, we have made it [as thin as possible], assuming a thickness that will withstand leather craft use.

We also wanted to create a modern design, so we eliminated all corners and gave all corners a slight curve.

The design of the metal fitting does not affect the artwork, making it suitable for any occasion !

(*See 12th image)

5.【Spring snaps shall not be deformed.】

PRIM/ FIOCCHI mountainous shape STUD can cause spring snap metal fitting deformation.

What do you think happens when a wallet or other item with this STUD is placed in a butt pocket and weight is applied to it?

Spring snap metal fittings are also deformed into a mountain shape!

The shapes that each manufacturer has produced over the years have meaning.

I believe that vendors who do not respect the makers and do not actually do leather crafting create such mountainous shapes.

We manufacture our tools with respect to the philosophy of each manufacturer.

Therefore, we do not make metal fittings that would drastically change the spring snap metal fittings that each manufacturer is particular about.

This is because SOCKET(Spring snap) is the main focus, and STUD is a supporting role.

*There is a correlation of the Metal fitting to the thickness of the leather.

Please refer to the 11th image.

Usage & Maintenance

-

User's Manual

-

Related items

Please feel free to inquire about anything and also asking for quotations.

Oka Factory & Co.,Ltd.

272-0827 5-10-7, Konodai, Ichikawa-city, Chiba

Monday - Friday, 8:30 a.m. - 6:00 p.m.

FAX +81-47-713-8661