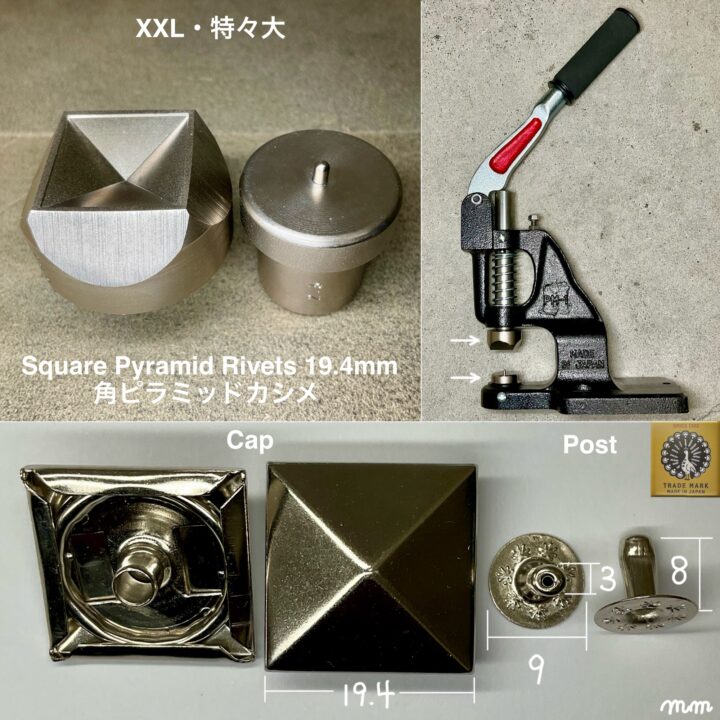

Hand Press Die (Square Rivets XL 19.4mm)

Hand Press Die (Pyramid Rivets)

Item Name

Hand Press Die (Square Rivets XL 19.4mm)

Size

-

Use

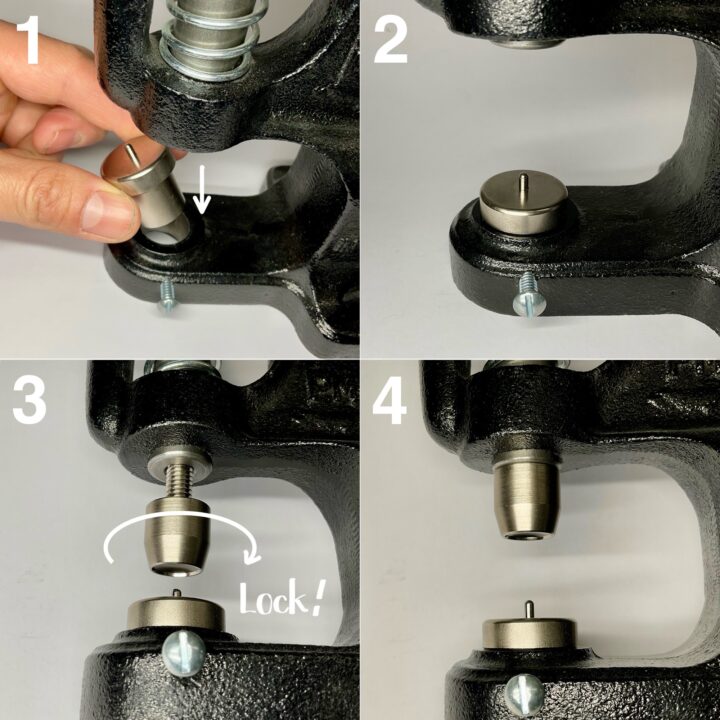

Hand Press Setting Dies to be attached to Hand Press machines.

Anyone can easily and accurately install metal fittings without making noise.

Hand Press Setting Dies designated as【Peacock】Genuine Products !

Characteristics

Hand Press Setting Dies designated as【Peacock】Genuine Products !

【Peacock】is a long-established Japanese hardware manufacturer founded in 1922.

For more than 100 years, it has been used for high-end accessories, bags, and leather goods in Japan and abroad.

Therefore, its durability and quality are second to none.

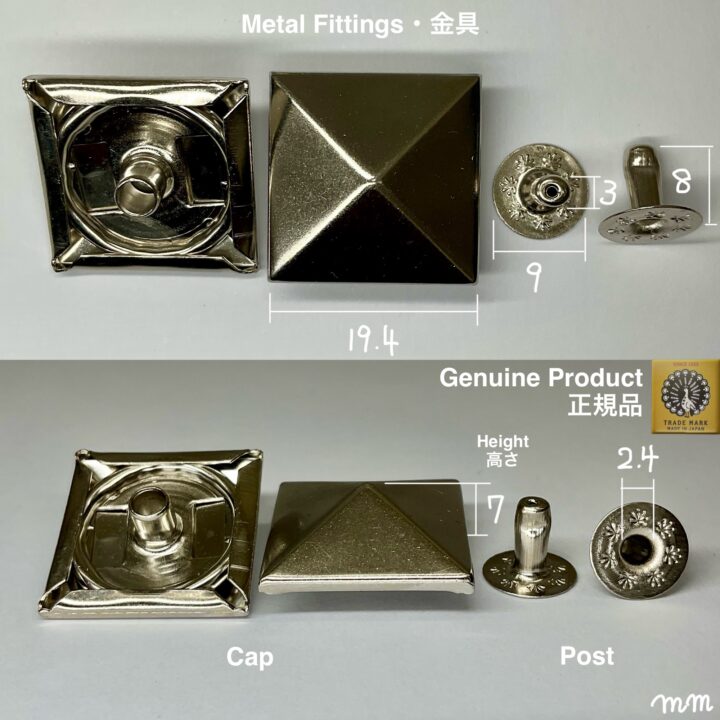

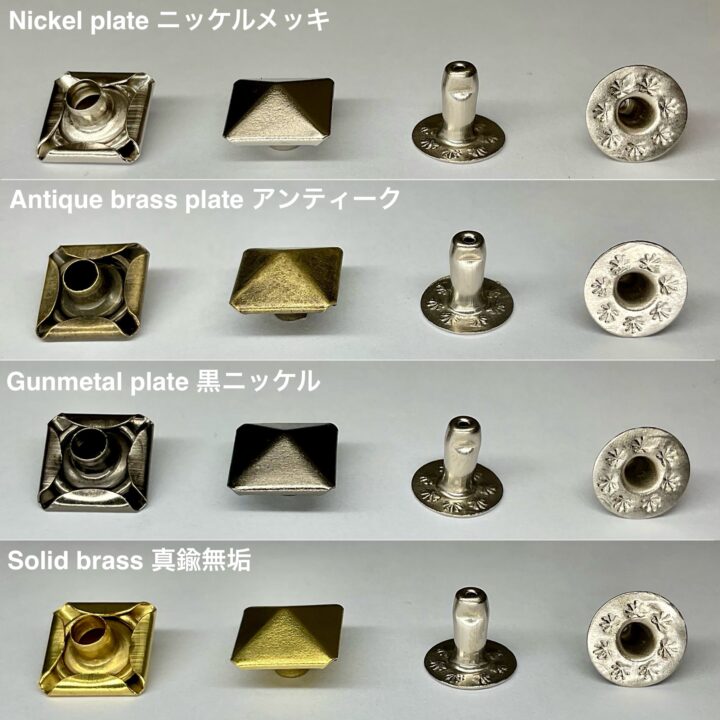

There are many different manufacturers of Rivets Metal Fittings around the world.

Just because the outside diameter is the same size does not mean that it is the same no matter which manufacturer is used.

Rivet Metal Fittings vary slightly in shape and R, depending on the Dies of the manufacturer producing them.

Strictly speaking, Cap wrapping (drawing process), Post shape (drawing process), etc. vary from manufacturer to manufacturer.

Using tools that do not conform to the metal fittings' standards will, of course, deform the metal fittings.

It is essential to use [tools made to the standards of the metal fittings manufacturer] in the process of fastening metal fittings.

Hand press setting dies sold on the Internet and other retailers range from inexpensive to expensive.

The common feature is that there is no mention of "which metal fitting manufacturer the tool was made for".

Even though metal fittings are the main tool, we are not particular about metal fittings.

Our company's fittings and tools are [genuine Peacock products].

For this production, we reviewed the Hand Press Setting Dies sold in the world from scratch.

We have created this product by considering "what is good and what is bad" from the viewpoint of our factory specializing in leather craft.

We were particular about [seven points].

1. To make a tool after the metal fittings are quantified in the drawing.

2. Tempered all parts of the tool.

3. To eliminate rough dimensional tolerances and unify with Hand Press (Made in Japan) standards.

4. The metal fittings shall be mirror-finished to prevent scratching.

5. To be plated.

6. To clarify the relationship between Dies and Metal fittings (Cap + Post).

7. To make a tool that can be stopped by hand with a special Setter for Upper Die.

【Characteristics】

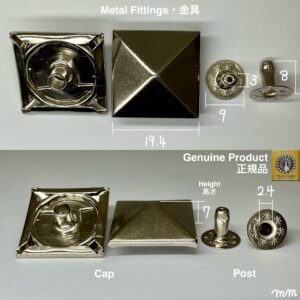

1.【To make a tool after the metal fittings are quantified in the drawing !】

The first thing we did in manufacturing was to quantify the metal fittings.

Peacock" has built up a 100-year long history of making metal fittings.

The rivet, which has been refined and sharpened over 100 years of history, is also the "final form of shape.

By quantifying the long history, we can for the first time make tools that match the fittings.

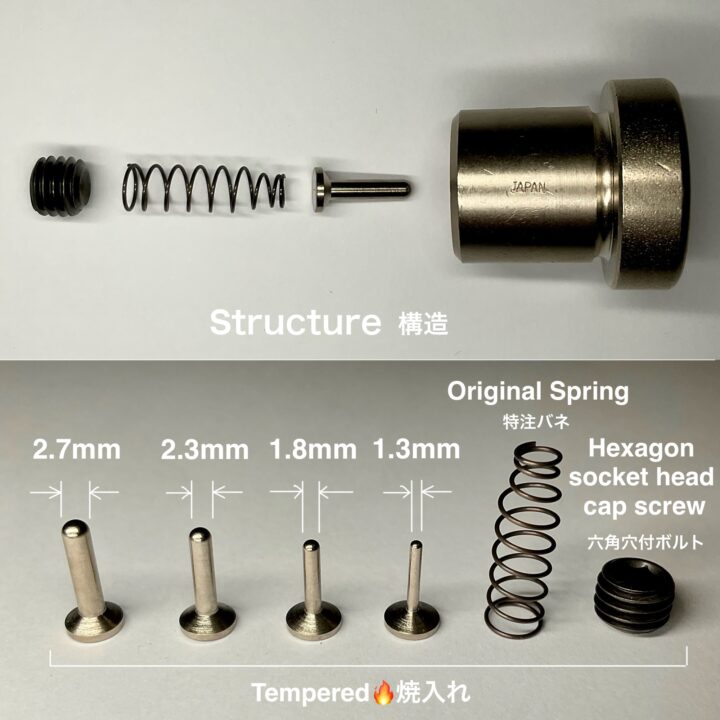

2.【Tempered all parts of the tool !】

We ordered various hand press setting dies from other manufacturers and measured them with a hardness tester.

The results did not indicate any hardness being hardened in all Dies.

In other words, it is the "hardness of the metal as it is" when nothing is done.

It looks baked, but it is not quenched accurately.

Hand press setting dies are designed to produce a large number of products.

Therefore, there is a big difference in quality between quenched and non quenched products.

If not hardened, metal wear will occur.

Wear can lead to deformation of fittings, loosening of screws in upper dies, and rattling of upper and lower dies.

All parts of our products are quenched and hardened.

All "upper and lower dies, lower die pins, lower die springs, and lower die screws" are hardened.

This makes for a long-lasting tool with excellent wear resistance and suitable for mass-production machining.

3.【To eliminate rough dimensional tolerances and unify with Hand Press (Made in Japan) standards !】

In this study, we dimensionally measured Hand Press Setting Dies of various other companies' products.

As a result, we found that even the same product has different dimensions and is not a uniform standard.

Our products are made for both upper and lower dies with dimensional standards that match Hand Press (Made in Japan).

For example, the dimensions of the part of the lower die that goes into the Hand Press

While other companies' products are roughly 18.8~18.9mm, we have unified ours to "18.94~18.95mm.

You can see from these figures alone that our dimensional intersections are strict.

This allows for accurate work without rattling.

4.【The metal fittings shall be mirror-finished to prevent scratching !】

The machining of metal fitting surfaces for other companies' products is lathe machining.

Because the round bar (material) is rotated and processed, processing scratches will inevitably occur.

These scratches "show up on the metal fittings" when the fittings are fastened.

Our products are particular about the mirror finish of the metal fittings.

Since there are no scratches on the metal fittings, the fittings can be installed as they are with their original beauty.

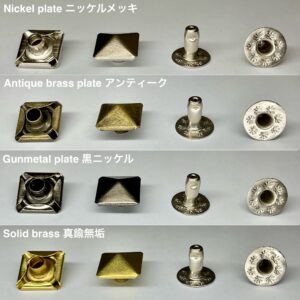

5.【To be plated !】

The surface treatment of other companies' products is often clear spray paint.

With paint, it peels off quickly, and rust will soon show up as it is used.

When rust surfaces, deformation of the metal fittings and contamination to the material they are fastened to can be a concern.

Our products are plated with a minimum film thickness.

Therefore, it is resistant to rust and will not damage metal fittings or materials.

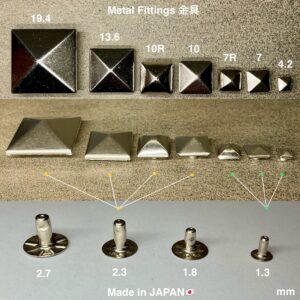

6.【To clarify the relationship between Dies and Metal fittings (Cap + Post) !】

Have you always bought Hand press setting dies as an Upper & Lower set?

Our products have eliminated this waste by clarifying the relationship between "Die and Rivets" standards.

Actually, there are only "4 types" of Lower Dies(for Rivets) standards.

It's basically "4 types", just with different lengths of Post's legs.

If you have 4 sizes of Lower dies (1.3/ 1.8/ 2.3/ 2.8), you can deal with all Rivets (MetalFittings).

Now that you don't have to have all your Dies in the Upper & Lower set, you can expand the range of your creations at a lower cost.

For details, please refer to the correspondence table in the image.

*Sales of single items are a little more expensive than those of upper and lower Dies sets. Please understand.

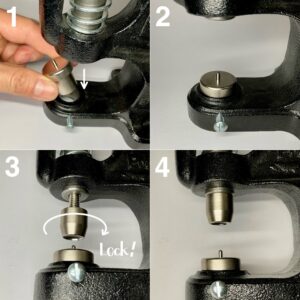

7.【To make a tool that can be stopped by hand with a special Setter for Upper Die !】

It is very time-consuming to use a Hand Press machine to stop a small number of Rivets metal fittings.

We created "Upper die setter" to eliminate this hassle.

We were particular about "four points.

① The entire product is subjected to a "hardening process" to improve wear resistance.

② Setter should be 15 mm thick.

Thick enough to absorb the impact of the upper die when struck and firmly stop the metal fittings.

Thickness to match W5/16-18 thread standard.

③The handles are non-slip so that work can be performed securely.

④The entire surface is plated to prevent rust.

You can easily stop the fittings by placing "Anvil (6sizes) or Anvil" underneath.

*Never use the lower die when hand hammering ! ! !

Lower die is not a tool designed to be stopped by hand!

Lower die is not designed to withstand the impact of striking !

Striking by hand with the Lower die by force will cause deformation !

Usage & Maintenance

-

User's Manual

-

Please feel free to inquire about anything and also asking for quotations.

Oka Factory & Co.,Ltd.

272-0827 5-10-7, Konodai, Ichikawa-city, Chiba

Monday - Friday, 8:30 a.m. - 6:00 p.m.

FAX +81-47-713-8661