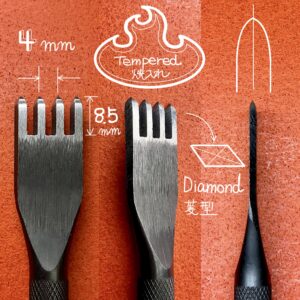

Diamond Hole Punches 4mm

Item Name

Diamond Hole Punches 4mm

Size

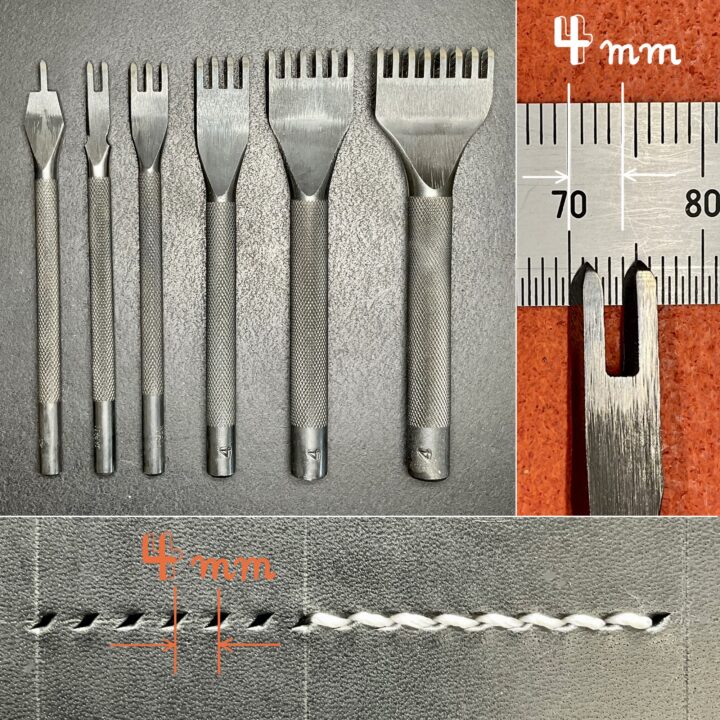

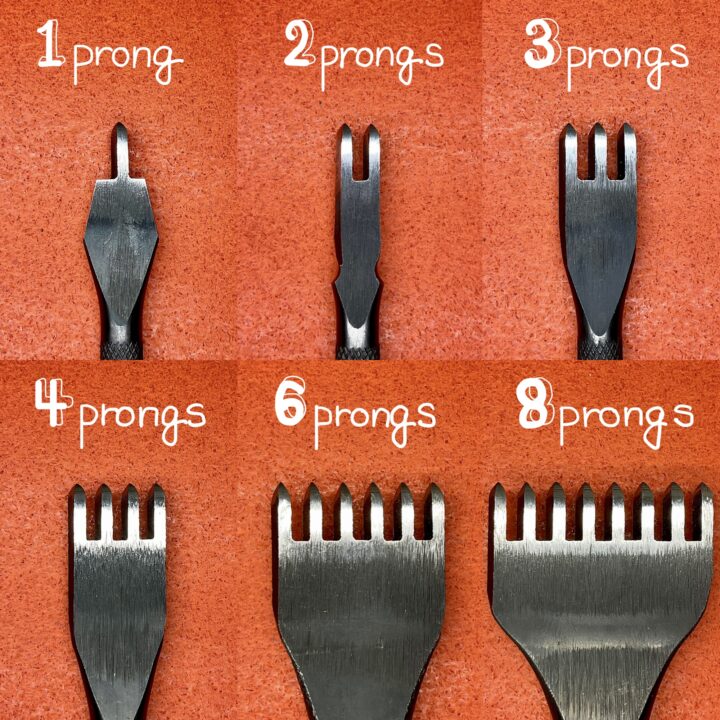

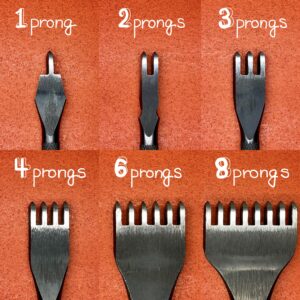

4mm(space between prongs) 1・2・3・4・6・8 (prongs)

Use

Punching tool for hand-sewing

Characteristics

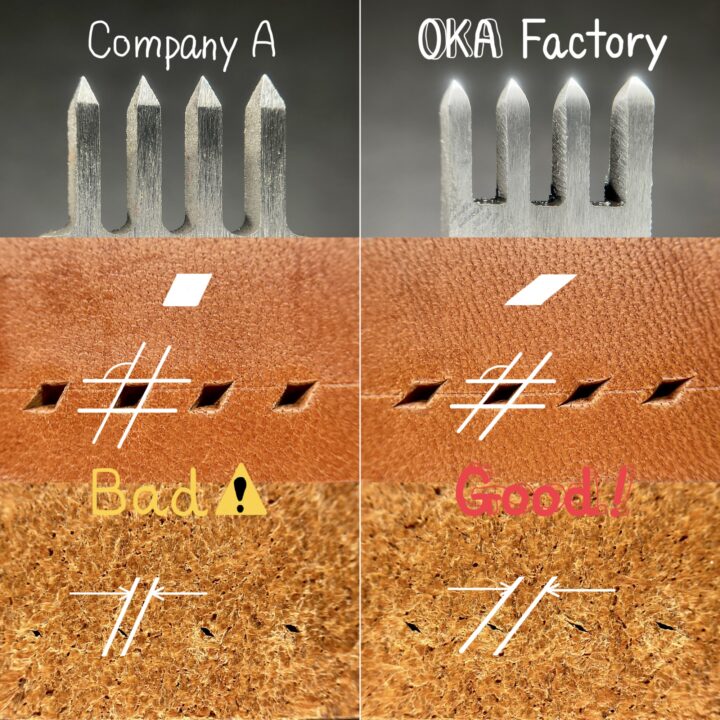

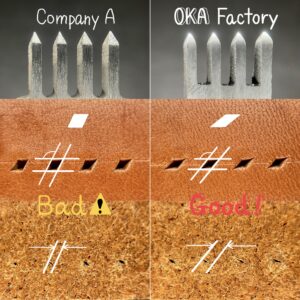

The hole shape of the conventional punching tool was close to square, not like a diamond. The blade had a rough finish so there was damage on the leather when you pull off the tool.

For smooth work, efficiency and a beautiful hand-sewn touch, we have developed this item.

・

The history of hand-sewing leather is long, and there are reasons for using diamond-shaped holes.

(1) Because the force when hand-sewing is applied diagonally, the leather is less likely to be torn by the force of hand-sewing.

Leather hand-stitched by hand is more durable than machine-stitched leather, because it requires much more force.

Diagonal Hole Punches are based on the same principle.

・

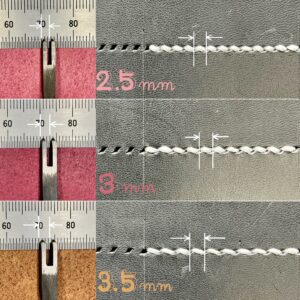

2) Leather Hand Sewing uses mainly #0 to #8 thick thread.

Sewing machine sewing uses a thin needle and thread, and the seam structure is different.

Leather hand Sewing uses thicker threads and needles, and Diamond Hole Punches are the minimum required holes.

In the long history of leather hand sewing, the diamond shape was the most suitable shape to meet the above requirements.

・

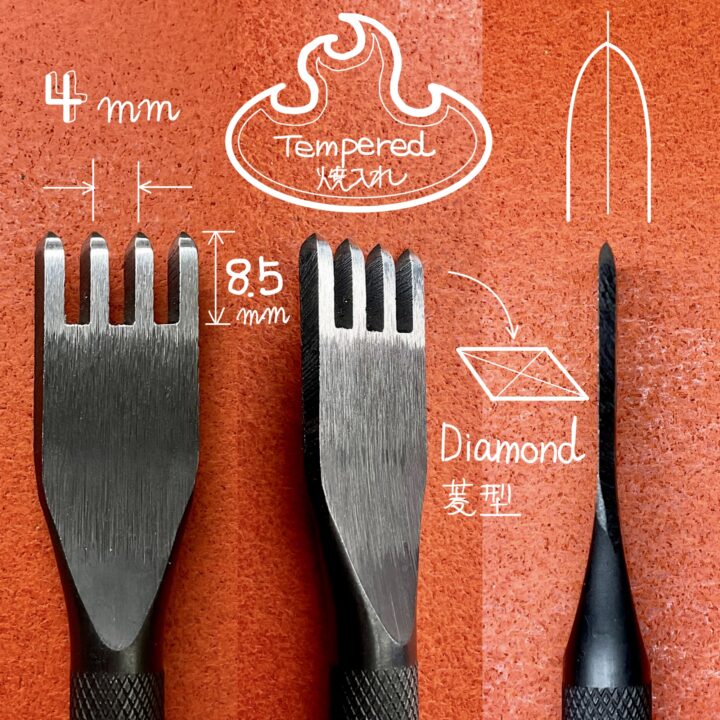

①The whole tool is tempered so there’s no bent or deformed tool.

Black coating prevents rust.

・

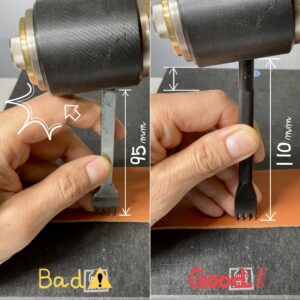

②The tool’s blade is sharpened and ground on a one by one basis so there’s no damage on the leather sheet when you pull off the punching tool from it. The blade part is covered with resin to protect it.

・

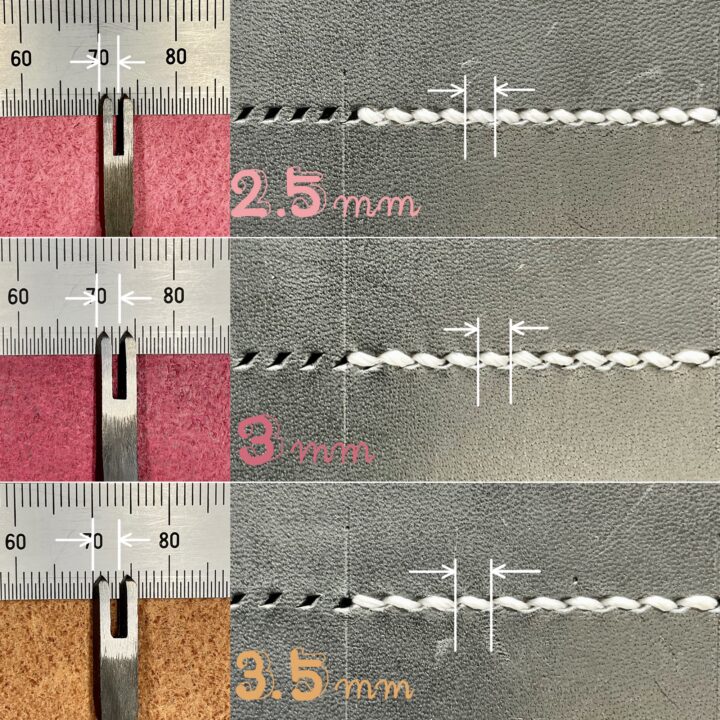

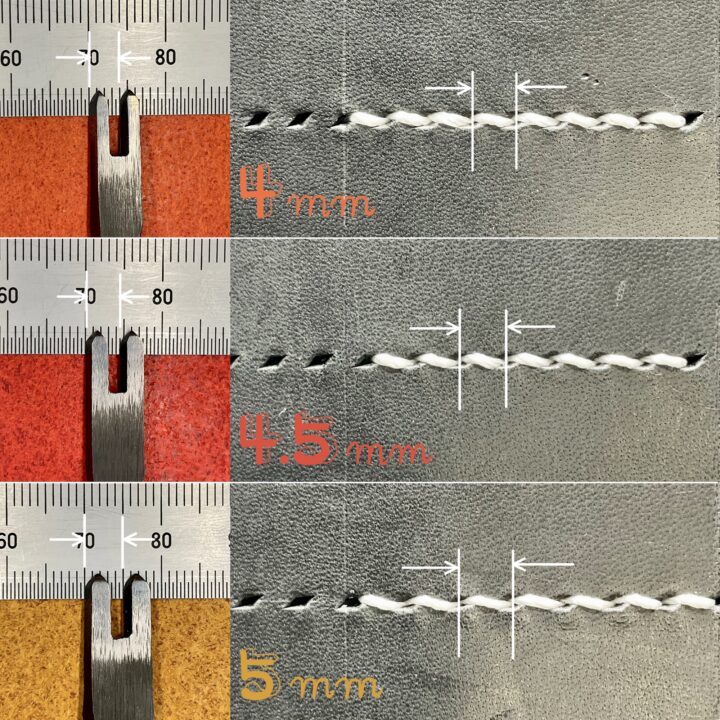

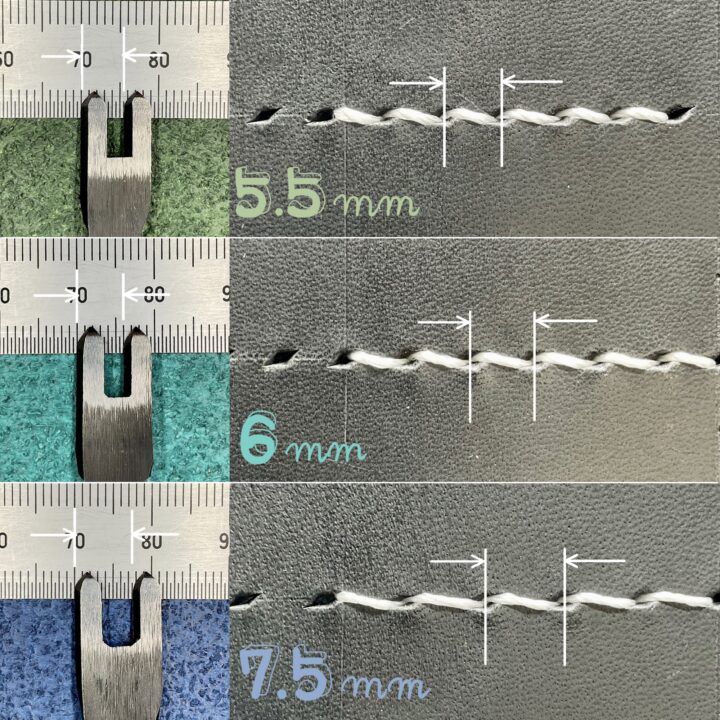

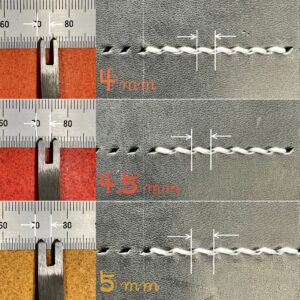

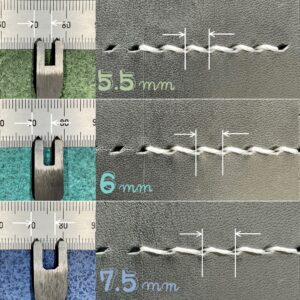

③We make the blade angle as sharp as possible so the hole shape can be much narrower and make the seam beautiful and clean.

・

④Knurling the body part makes it nonslip so as to get easier grip to work with.

・

⑤Engraving the size(space between prongs) and “MADE IN JAPAN”.

Usage & Maintenance

User's Manual

Related items

Please feel free to inquire about anything and also asking for quotations.

Oka Factory & Co.,Ltd.

272-0827 5-10-7, Konodai, Ichikawa-city, Chiba

Monday - Friday, 8:30 a.m. - 6:00 p.m.

FAX +81-47-713-8661